Company: SINTEF

Industry: Poultry Processing

DENSO Products Used: VS 087

Company Location: Norway

Website: http://www.sintef.no

PROBLEM

In one of the few industries where automation seems to have leveled out, a breakthrough application has now successfully demonstrated how robots can perform even the most challenging food handling usually done manually by human operators.

SOLUTION

At SINTEF, Scandinavia’s biggest independent research center, engineers developed the “Gribbot”, a specially designed system using a DENSO VS 087 robot for processing chicken breasts.

“This part of the chicken is the most costly one, so meat producers are naturally concerned about the yield”, explains SINTEF’s research leader for the Gribbot, Dr. Ekrem Misimi. “However, automating this process, as any procedure that relies on human hand-based operations, is very challenging. With the Gribbot, we wanted to show to manufacturers and food retailers that this kind of automation is possible today.”

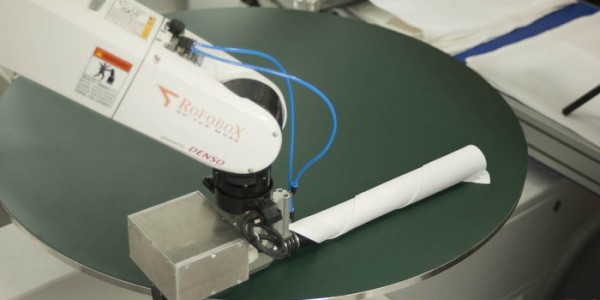

The Gribbot is based on the center’s experiences with several robot-based projects such as RoboTrim project, also using a DENSO VS 087, which was used to trim objects in a salmon fillet. This experience with the DENSO V087, primarily because of its flexibility and the ease of use, has opened up a sea of opportunities in robot-based automation in the food industry for handling and processing operations.

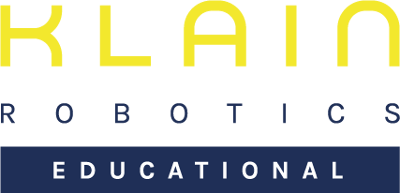

The main goal but biggest challenge was to generate a satisfactory yield comparable to that of human operators – not an easy task, given the slippery surface, soft texture and the high variation of the chicken breasts as such. “We had to implement the scraping of the fillet from the carcass along the rib cage so that a minimal amount of rest meat was left on the carcass. This was an even bigger challenge for the entire system – from the detection of the gripping point with machine vision as well as creating an optimal path movement for the robot arm”, says Dr. Misimi. The biggest challenge, however, consisted in the development of the gripper. The chicken fillet had to be handled with care so that it would not be teared off or squeezed too hard.

RESULT

The Gribbot consists of a transport system, a machine vision subsystem, a robot arm and a compliant gripper. The DENSO VS 087 robot-based concept is using 3D machine vision – the Gribbot’s “eye”, the DENSO robot serves as its “arm”, and the compliant gripper, which was designed by SINTEF, functions as the Gribbot’s “hand”.

SINTEF researchers opted for the DENSO VS 087 because it as an IP67-rated robot suitable for working with food raw material. It is also the fastest robot arm in its class, with a very short cycle time. “Having a robot that is easy to program is very important to us”, says Dr. Misimi, “as we can quickly develop a prototype.” Another reason for the DENSO V087 was the fact that it could be programmed entirely in a LabView environment, using the DENSO robotic library developed by ImagingLab/DigiMetrix. All of the equipment is interlaced in LabView, including the 3D machine vision. The system’s gripper is also controlled via the built-in solenoid valves in the robot arm, alleviating the researchers for long loss cables. SINTEF was also able to use the built-in electrical wiring of the DENSO V087 to send and receive necessary signals from the gripper. The machine vision is connected through USB 3.0 to the controlling computer and accessed via LabView.

The Gribbot can process a chicken breast in about 2-3 seconds, which – in a Norwegian chicken industry context – in perspective, translates into a concept based on one or more Gribbots being able to replace up to 30 human operators (8-12 per shift), resulting in huge savings for the industry and releasing the employees from highly repetitive tasks.

While it’s still a research project, the Gribbot demonstrates a promising technology readiness level that needs one more development cycle prior to potential industrial prototyping. The potential benefits of the Gribbot for the food industry are enormous – the Gribbot can optimize the entire production, making it both more cost- and operations-efficient due to the automation of the harvesting procedure. It also shows an optimal utilization of raw material very close to the one achieved by human operators. In the future, the system could also be applied to other, similar tasks throughout the food processing industry.

Movie available here: https://youtu.be/9BcqXaf0F2E