DENSO Robotics shows how to further optimize industrial automation. In an exciting project called “DENIoT”, DENSO Robotics, using a Microsoft Azure cloud platform, and partners DeROBÓTICA, ENCAMINA and ENTRESISTEMAS demonstrate how cloud services greatly optimize robot controllers’ performances for automation processes.

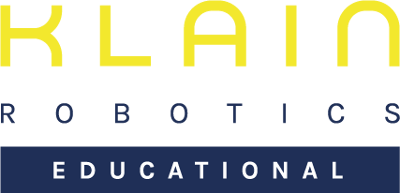

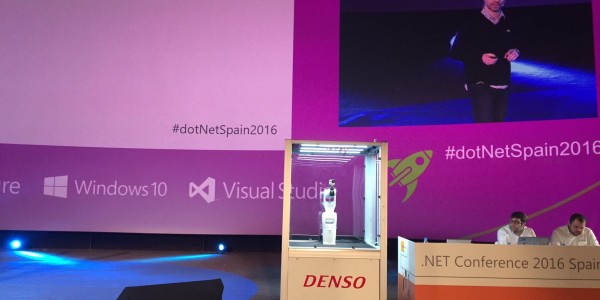

Leading the way to a new level of Industry 4.0/IoT applications, DENSO Robotics and partners recently showed how industrial automation in “smart factories“ can be made more efficient, safer, and reliable with already existing software and technologies. At the center of the demonstration, part of the “DENIoT” project at DENSO Robotics, were a DENSO Robotics VS060 and the cloud platform Azure by Microsoft. Azure is a collection of integrated cloud services, such as analytics, computing, database, mobile, networking, storage and Website. The demonstration was held at Microsoft’s high-caliber .Net conference in Madrid (Spain).

Partners in the “DENIoT” project and demonstration are DeROBÓTICA, the Iberian sales organization for DENSO Robotics; ENCAMINA, a Spanish consultancy company specialized in Microsoft products, including Azure; and ENTRESISTEMAS, an industrial automation and system integrator specialist. For the demonstration, DENSO Robotics provided the robot and controller, ENCAMINA handled the communications between the robot, the cloud and the various devices, while ENTRESISTEMAS programmed the actual robot movements.

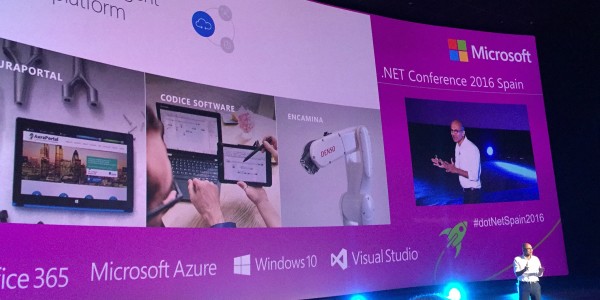

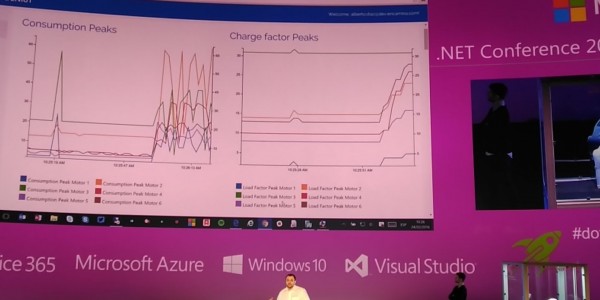

The well-received demonstration aimed at showing that robots performances can be greatly optimized today by using the advantages a cloud platform such as Azure offers. The platform was connected to the DENSO robot controller in order to collect and interpret data using big data analytics and other techniques. These data were turned into actionable information. In the actual demonstration, the VS060 had been programmed to perform up to 9 different movements, mostly pick-and-place. “Our objective was to show that we can optimize robot performances by using already existing technologies and processes. By monitoring and analyzing the robot data, we can not only interact with and control it from virtually anywhere, but we also facilitate machine learning, which further enhances efficiency and performance,” says Pablo Olivas González, Managing Director of DeROBÓTICA. The data monitored included parameters such as the robot arm’s speed, acceleration, positions and (joint) angles.

The benefits of “DENIoT” for implementing Industry 4.0/IoT applications in industrial automation are obvious: An easy connectivity of machines and devices, a real-time monitoring of processes, a scalable application, machine-learning (analysis and prediction) and a multi-platform system adaptable to an industry’s specific needs. In addition, “DENIoT” can be controlled from anywhere using various devices (PC, tablet, even a smart phone) and offers a high level of interaction and control for users.

The combination of a DENSO robot and Microsoft Azure was a perfect match. “We opted for Azure“, explains Pablo Olivas González, “because we needed a high-performance cloud platform which can process a high amour of data and easily compatible to various systems. Last but not least, it was important to have a machine learning option integrated, which Azure offers.”

DENSO robots are especially suited for Industry 4.0/IoT applications as the RC8 Controller is highly flexible and easy to integrate into any system. This is crucial as the key to any successful IoT solution is a simple, fast and reliable coordination between all parts of the system. There are many platforms the DENSO RC8 Controller can work with, including LabVIEW, HALCON or PLC industrial networks (i.e. ProfiNET, ProfiBUS, etc.). For the “DENIoT” project, ORiN was the most important one. ORiN (Open Resource interface for the Network) is a software development interface, that allows to interact with the robot at high-level languages such as C#, C++, etc. This unique capability of programming at high-level languages permitted a very easy integration of the software platforms with the DENSO robot and with Microsoft’s Azure.

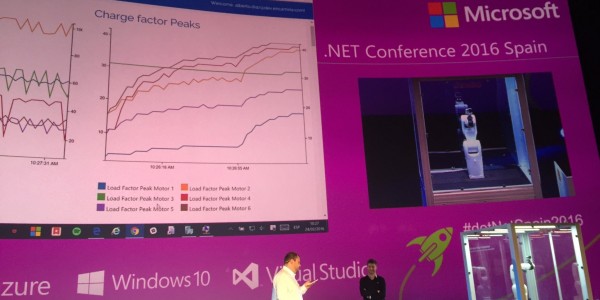

During the “DENIoT” demonstration, the robot was also controlled via Microsoft’s intelligent voice command system Cortana: Basically, it translates verbal commands into robot movements (through the cloud). In the demonstration, each of the nine movement commands was assigned a number. The command “move”, for example was assigned the figure “10”, which was sent to the robot in order to perform this specific movement. Voice command interaction will become more important as the human-robot-collaboration will be increasing in the future.

Of all the movements the VS060 performed, his last was the most popular one with the audience: The robot simply took a selfie!